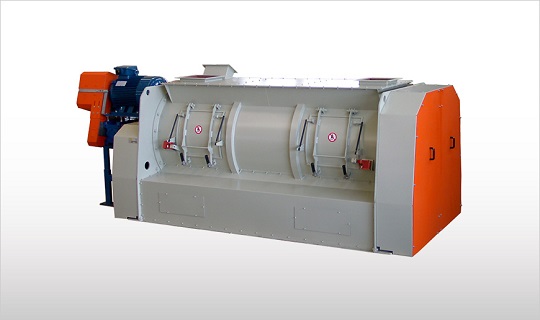

Features

Capacity: 165 ~ 20,000 litres per batch

Mixing ratio: 1/100,000

Variation coefficient (CV): between 3 and 5

Possibility of adding up to 20% of liquid

End bearing assemblies with various types of air or nitrogen-purged shaft seals or grease sealing

Heavy-duty mixing chamber manufactured from carbon steel, anti-wear steel or 304L / 316L stainless steel

Stainless steel surface finishing: grit silking, mirror polishing, glass bead blasting

Wide range of mixing tools (boxed ploughshare, toothed ploughshare, blade, toothed blade-type), available with anti-wear coating on request

Benefits

Short mixing time (1 ~ 4 min)

Maximum mixing homogeneity

Excellent reproducibility of batches

No product deterioration or damage

Low maintenance

Durable machine

Power rating adapted to application Easy cleaning and access to all internal parts of the mixer Mixing know-how and test facilities Options